With heightened passenger concerns about in-cabin COVID-19 spread, there has been a rising demand for airlines to increase their decontamination protocols. But with recirculated cabin air being standard on commercial aircraft, could ionisation purification be the additional cabin environment mitigation we're looking for?

For decades now, HEPA has been the gold standard in-cabin air filtration by promising the removal of 99.97% of airborne particulates measuring 0.3 microns. Although highly effective, this system solely works in capturing viral, bacterial or pathogenic particulates. However, it does not neutralise contaminates before making their way into the HEPA filtration system.

READ MORE ABOUT:

Addressing cabin air in the world of unseen elements

This is where cold plasma ionisation purification technology comes into play as mitigation technology to work in tandem with HEPA filtration.

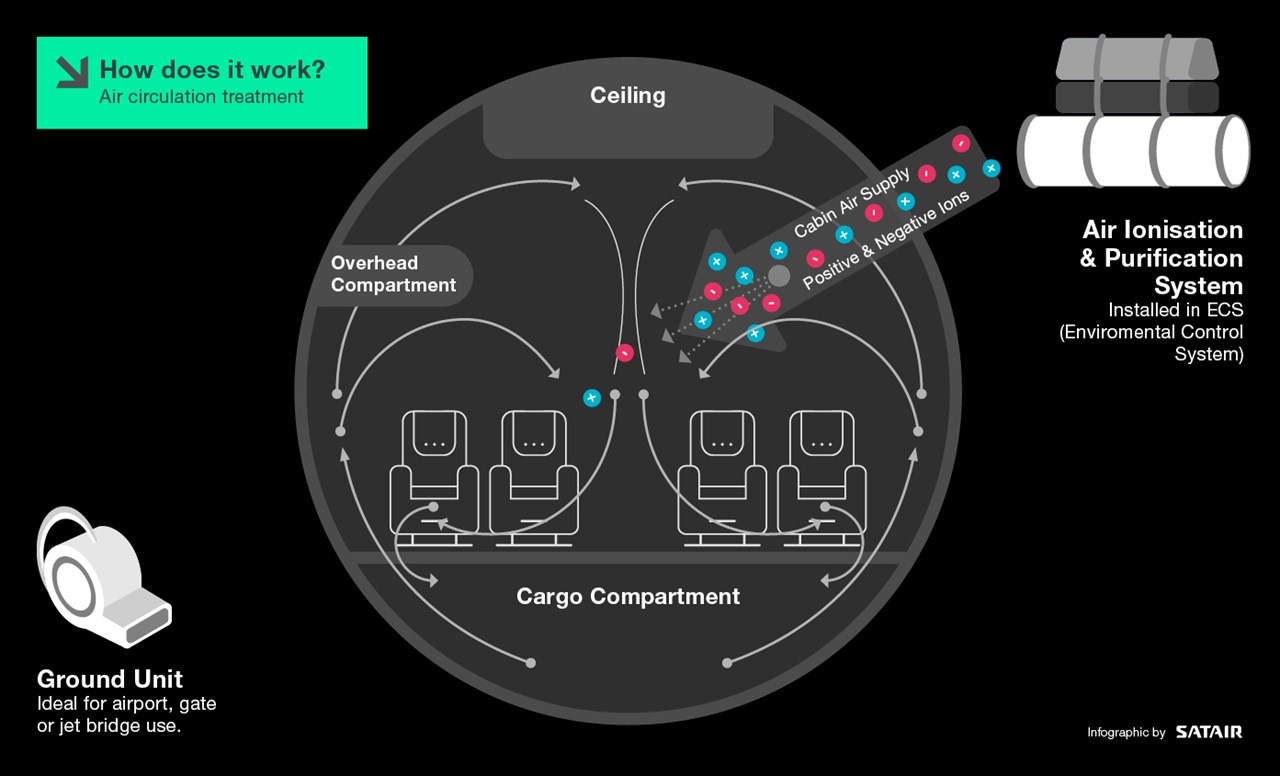

How does ionisation purification work?

Ionisation is a naturally occurring phenomenon that happens in the air all around us. It is Nature’s way of establishing checks and balances between various forms of bacterial and viral cells.

The needlepoint bi-polar ionisation technology (NPBI™) developed by the American company Aviation Clean Air (ACA) builds on Nature’s methods by increasing the ionic density within the cabin to neutralise pathogens. Purification through ionisation is a proven technology, with many already existing applications. In fact, recently hospitals including Johns Hopkins, Children's Hospital Boston and the University of Maryland Medical Center have already embraced the technology.

We spoke with Jonathan Saltman, President/CEO International Aero and Member at Aviation Clean Air (ACA), to have him explain this technology in more depth:

"To start, I guess we need to establish that pathogens can’t fly. They need to hitch a ride on something like dust particles or water vapour. Because of their nature, ions like to attach themselves to Hydrogen and Oxygen molecules in the water vapour present in the air. These ions have the property of clustering around microparticles, gases, airborne mould spores, viruses, bacteria, etc."

READ MORE ABOUT:

Ionisation purification technology: What does it cost?

What kind of contaminants can you mitigate with ionisation?

While there is currently a more imminent need for such a solution, ACA has been developing and testing ionisation technology for years. It has been tested to be effective against the airborne and surface spread of viral strains H1N1, H5N1 and SARS as well as bacterial contaminants like Staphylococcus (STAPH), Methicillin-resistant Staphylococcus aureus (MRSA), Mycobacterium tuberculosis (MTB), Clostridioides difficile (C.Diff) and Escherichia coli (E.coli).

Jonathan Saltman of ACA explains:

"These energised ions travel through the cabin air like microscopic magnets seeking to attach themselves to free-floating particulates. When the ion comes in contact with a viral or bacterial particulate, a microbicidal chemical reaction takes place on the virus or bacteria cell membrane surface. This microbicidal reaction effectively renders the viral or bacterial cell inert and unable to reproduce."

However, of course, the most pressing concern of our current times is the airborne and surface spread of SARS-CoV-2 (COVID-19). Recent tests conducted by various independent labs have found that ACA’s NPBI™ technology can render 99.4% of COVID-19 viral particles inactivated on a stagnant surface within thirty minutes.

Combine this with a HEPA filtration system to then capture the inert viral particles, and cabin air purification takes on a new level, as the ionisation immediately mitigates contaminants in the cabin environment, before the air reaches the HEPA filter.

Does an increase in ionic density affect passengers?

In effect, no. There are naturally occurring instances of extreme ion density, which have no known negative impact on human physiology. Waterfalls are a perfect example, measuring ion density tens-of-thousands units higher per cubic centimetre than in normal air.

So, therefore, it could be said ionisation purification is 100% green and works by accelerating Nature’s cleaning process with no chemicals added. In addition, needlepoint bi-polar ionisation technology (NPBI™) does not create harmful chemicals, emissions or gases, which is in contrast to other similar technologies offered in the market today

Both airborne and surface contamination

Where ionisation purification truly shines, is in its ability to marry the purification process of both surface and air. Traditionally, cabin air purification and cabin surface decontamination are two whole separate systems—one automatic, the other manual.

However, ionisation is effective against both airborne and surface contamination, so it has the potential for drastically reducing the current decontamination cycles between flights. Furthermore, ionisation takes out the risk of human error in the manual cleaning processes described in an earlier article, as it is always on and reaches all parts of the aircraft interior.

Is it future-proof?

Looking into the future, airlines must begin preparing their operations around the reality that community spread of viral and bacterial pathogens will be top-of-mind with many passengers for years to come. Proactively setting up in-cabin safeguards to mitigate those risks will be a real differentiator.

When looking specifically at ionisation technology, the life cycle of this new proprietary ionisation technology, ACA’s NPBI™ unit has an 87,530 hour MTBR (Mean Time Between Removals). There is no additional training or maintenance required, so the minimal investment for such a ground-breaking and forward-thinking safeguard seems like an easy choice to make.