Five years ago, the narrative of the MRO industry couldn’t be more different to how it is today. Almost excessively dependent on human labour, it lagged behind other industries in terms of technology adoption – by something in the region of a decade.

Nevertheless, approaching 2019 the mood was optimistic that new hardware and software advances were on the verge of opening up the industry to automation, spurring a potential shift from human touch to human-led.

Nobody was expecting robots to replace aircraft mechanics overnight, but everything was pointing to a future in which they would be heavily aiding them, thus reducing MRO costs for aircraft operators and lessors.

Such was the consensus at MRO Europe in October 2018 where the Satair Knowledge Hub took part in the conversation. Let’s recall what was said and then assess how many of the expectations became a reality.

READ MORE ABOUT:

The five biggest challenges with additive manufacturing.

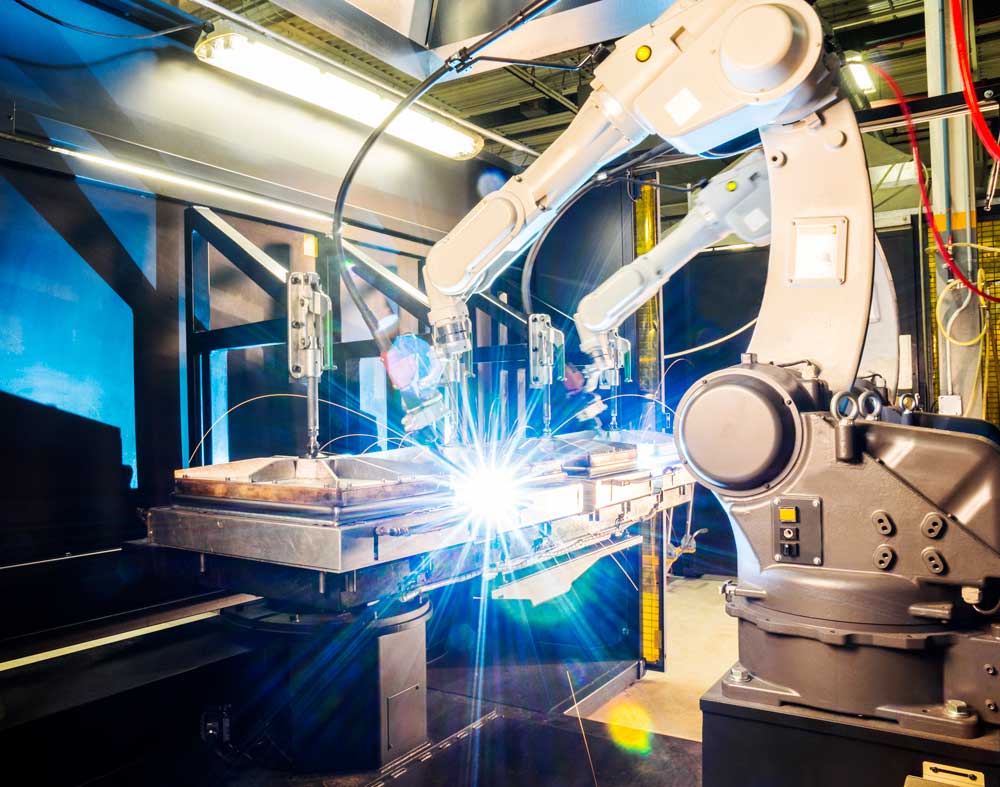

Robotics on the rise

DEC 2018:

Robotics in MRO is a hot topic. In fact many organisations are pursuing robotics in one way or another. Robotics, therefore, is one of the fastest growing new MRO technologies to keep an eye out for.

DEC 2023:

Robotics was not a particularly hot topic at MRO Europe 2023, according to the experts who took the time to talk to the Satair Knowledge Hub.

DEC 2018:

When we think about robots, it’s often veiled in the fear that robots will make our jobs irrelevant. At the moment, this couldn’t be further from the truth.

While not appropriate for all applications, robots have a number of potential uses for achieving greater efficiencies in the MRO world. This is particularly critical now, as skilled labour is in short supply in the industry and labour costs are climbing, commented Goh Poh Loh, Executive Vice President at Singapore Technologies Aerospace:

“We’re looking at how robotics can help us improve efficiency. Labour costs are rising rapidly, so we basically want to see how we can automate and use robotics to improve efficiency and do better.”

DEC 2023:

Certainly the industry does not consider automation, and other emerging technologies such as AI-driven data analytics, as a potential threat to jobs, even if they do promise to save labour resources.

DEC 2018:

More often than not, robots simply aid labour with routine or precision-orientated tasks. They can even be used to take on labour-intensive work that could pose a safety risk for humans.

DEC 2023:

This is still very much the direction outlined for the use of robots

DEC 2018:

We’re seeing MRO robotics applied to everything from single parts repairs and carbon fibre machining to intricate inspection tasks through miniaturisation, whereby robots can be used for the inspection of components that are otherwise difficult for humans to gain access to.

There are some robotics solutions in the pipeline that are sure to be future game-changers, such as Rolls-Royce’s ‘swarm’ robots. These 1-cm-long robots would be designed to crawl through engines, capturing images and sending them back to technicians for diagnostics. They’re the first step in Roll-Royce’s ambition to develop a series of miniature robots that could remove and replace defective components.

While definitely inspiring, such a solution is far off from being realisable, and can generally be seen as the exception, rather than the norm, of how robotics is being used and talked about in MRO today. For the most part, robotics are being discussed as valuable for automation of inspection tasks and restricted to less critical aircraft systems. While new applications are certainly on the horizon, it may be a while before we see them.

DEC 2023:

Not much more has been revealed about Rolls-Royce’s ‘swarm’ robots following the flood of information released in July 2018. Back then, maybe Rolls-Royce jumped the gun a little when it claimed they were 1 cm in length and ready to be ‘parachuted’ into the heart of an engine via a ‘snake robot’. Video footage from the same year clearly showed they were still 40 to 50 mm, and there has been limited coverage of their subsequent miniaturisation, despite the efforts of technicians at the Wyss Institute at Harvard University. This late 2021 report suggested they were 15 mm in length, but there was still a long way to go.

Drones in the sky

DEC 2018:

Drones is another hot topic and it's another future MRO technology to keep an eye out for. Often spoken about in the same vein as robotics, drones are being used today for applications, such as remote plane inspection.

DEC 2023:

Again, the buzz around drones has quietened in similar fashion to robotics. At MRO Europe 2023, they were not mentioned by any of the experts in connection with what excited them most about ongoing developments in the industry.

DEC 2018:

EasyJet and Thomas Cook Airlines, for example, make use of the RAPID (Remote Automated Plane Inspection and Dissemination) system, an autonomous drone for inspection of the exteriors of planes.

DEC 2023:

Thomas Cook Airlines went bankrupt in 2019, but EastJet continues to use RAPID, which has been fine-tuned to spot imperfections on an aircraft’s exterior as small as a square millimetre. RAPID drones can be operated remotely if onsite technicians have no experience handling them, although minimal training is required to do so. Today an inspection of an A320 takes just 30 minutes, almost a fiftieth of the 24 hours it took to do so manually.

DEC 2018:

Facing similar friction as robotics in general, drones are seen as a handy tool, but there is still an overwhelming scepticism in the industry with regard to further applications. It’s widely agreed upon in the industry, however, that despite scepticism, progression seems inevitable.

The slow rate of adoption, when compared to other industries, is not exactly due to a lack of availability or opportunities – drones have become increasingly available at more affordable price tags.

Instead, the sentiment seems to be that the use of drones, or robotics for that matter – not particularly flexible or suited for process adaptation at this moment – would be a risky move, or at the very least prove inefficient, as line maintenance might need to check up on their work.

On top of this, you have the bad press that drones have been receiving because of legislative crackdowns and negative uses of the technology. So maybe robots and drones won’t be running the maintenance game anytime soon, but all evidence points to its increased prevalence.

DEC 2023:

This was a pretty sound analysis of what might happen heading into 2019, and certainly other technologies have been proven to be more beneficial. Still, there remains an inevitability about the future use of drones in line with the increased prevalence of air taxis and logistics drones that many predict will be filling the skies in the near future, using vertiports with the same frequency we use airports today.

READ MORE ABOUT:

How do you foster an innovative environment? Join a group of aviation executives as they discuss their strategies.

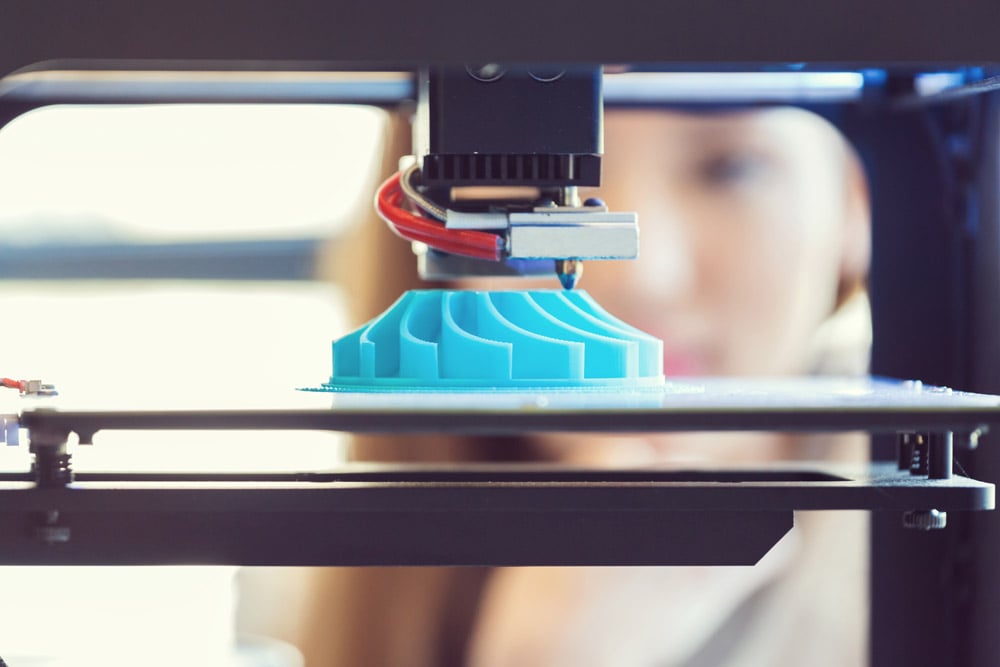

Additive manufacturing gaining ground

DEC 2018:

Another widely discussed topic being pursued already is additive manufacturing (AM), which refers to the use of computer-aided-design (CAD) software or 3D object scanners to create 3D printed goods.

As a future MRO technology, AM can enable the ability to seamlessly print replacement parts that are strong, durable, lightweight and quick as well as inexpensive to create – not to mention, they dramatically reduce inventory costs for maintenance providers.

As the name implies, AM involves adding material in layers to create an object. This process, as opposed to traditional manufacturing, which involves carving or shaping the final object, lends itself to less scrap or waste in the process.

A true revolution, additive manufacturing is being used by most of the larger MRO providers these days, but not to its fullest potential. For now, AM is being used on the less crucial components – such as cabin components – and is yet to be used on the more important structural components.

For that, OEMs are still generally relied on, although this is changing. Companies such as Lufthansa Technik and Air France Industries KLM Engineering and Maintenance are pursuing metal printing to apply AM to a wider variety of components.

With in-service feedback capabilities, AM parts can be continuously improved, as new specifications can be inputted with ease at the next printing. This inexpensive iteration definitely ups the likelihood that AM parts will quickly become competitive and have a high likelihood of reshaping the way aircraft components are manufactured in the long run.

DEC 2023:

Given the buzz surrounding AM five years ago, it was no surprise when Lufthansa Technik last year confirmed that a metal component produced by a 3D printer had been approved for aerospace use by EASA – a milestone for AM. The part in question, which was developed in cooperation with Premium AEROTEC, was an anti-icing system for an engine.

READ MORE ABOUT:

What are the opportunities and risks associated with additive manufacturing?

Utilising AR for MRO training

DEC 2018:

The interest in Augmented Reality (AR) as a game-changing technology hasn’t waned since it grabbed, and then lost, the public’s attention with Google Glass back in 2013. With regards to how the technology could be useful to the MRO industry, it has always been plagued by questions of how practical and cost-effective it would be to implement. We wrote about this in the article Augmented Reality in aviation MRO: Is it bleeding edge or leading edge?

There seems to be one area of exception where AR is influencing real change: MRO training. In a seminar with Wanda Manoth-Niemoller, the Commercial Development Manager of KLM, she spoke about how Royal Netherlands Aerospace Centre (NLR) and KLM have begun an MRO training course. It utilises multiple Microsoft HoloLens AR goggles to facilitate collaboration and instruction, while trainees walk around a scaled 3D model of an aircraft and its parts and systems.

“The way we did it, is that all the glasses are connected, which means that each of the students sees the same thing,” explained Manoth-Niemoller as she described a group training process. “It’s not VR, the students can see through the glasses. They can see each other. They see the same image so they can discuss things and collaborate.”

“It also changes the process of teaching. It’s not the instructor showing an image and describing it; it’s basically the students seeing the same image in a space and working together.”

As more and more digitised models of engine and aircraft parts become available, this form of training will vastly overshadow traditional forms of MRO training. The ability to simply remove and expand areas of an engine or part, and to discuss collaboratively, will significantly increase the timeframe and efficiency in which new generations of technicians and operators are on-boarded into the industry.

DEC 2023:

Unsurprisingly, the use of AR for MRO training, along with other emerging applications, really came into its own during the pandemic to the extent it has become the new status quo for the industry. Its increased usage – the industry predicts 72 percent of all MRO operations will use AR in at least one application by 2030 – and continuous development is credited with reducing downtime, making all MRO processes more efficient and reducing the carbon footprint incurred by technicians travelling from airport to airport. The AR, which has also proved popular with various countries’ militaries – for engineering as well as maintenance training.

Blockchain in MRO: The ongoing saga

DEC 2018:

Since first taking the stage in 2008, Blockchain has captured the attention and curiosity of industries around the world. From its beginnings as a misfit cryptography system used to solve the double-spending problem with crypto-currency to the herald of a new era of secure system management, Blockchain has continuously held its position as a leading technology.

During the conference, we sat in on a session with Hadi Mohamed Shakir, Chief Technology Officer at GI Aerospace. He spoke about how Blockchain can be used to improve record-keeping, digital twinning and faster lease turnover while maintaining a high standard of data privacy.

Hadi explained that the high standard of security functions by using Blockchain to create a secure ‘signature’ and blockchain ledgers. Essentially, it would allow businesses to create preferred lists of individuals that would have access to a blockchain signature, giving them access to whatever records or data that was shared. Anyone outside of the ledger would be unable to break the blockchain encryption to view the data.

We also visited a larger session with the MRO Blockchain Alliance, a newly formed partnership between Safran, SITA and Sky Republic, where we heard what they think on what Blockchain will mean for the aftermarket and part supply.

“Today, what is interesting is how Blockchain applies to the tracking and movement of parts. In terms of business value and cycle of technology, we expect that starting from next year [2020] will see the largest growth in the use of blockchain technology,” says Aurore Duhamel, Product Manager at SITA, provider of aerospace IT. “As people start to implement pilot supply chain programs, we’ll begin to understand which type of business models and areas work best for this technology.

“We expect by 2021-22, the market will be robust and mature enough for vendors to start introducing blockchain products that will bring true business value to the industry.”

You can learn more about how utilising Blockchain to connect the many loose ends in the supply chain will inevitably prove revolutionary to aftermarket and part supply industry. We also reported earlier this year on how Deloitte and Parts Pedigree, a newly formed startup of aerospace and technology experts, took blockchain technology from its proof-of-concept stage to the operations floor.

Based on the thoughts and insights from our time listening to the MRO Blockchain Alliance seminar, it appears that moving forward into 2020, many others will be racing to bring blockchain solutions to the market.

DEC 2023:

Certainly the wave of blockchain solutions continuing to have an impact on the market has not stopped: from traceability technology that makes it relatively easy to detect fake parts used in the aviation supply chain industry, to bookkeeping applications that enable MROs, OEMs and airlines to keep records of all their parts and materials. Nevertheless, many players in the aviation supply chain industry continue to only keep track of configuration data in their own systems, and this is holding blockchain back from fulfilling its potential. Fortunately there are other incentives to use shared solutions, as blockchain applications have a number of other potential uses, according to Deloitte. Among them are: redefining engine and parts leasing through ‘smart contracts’; simplifying revenue sharing and money exchanges; and encouraging loyalty programs (often using a common digital currency) that enable passengers to benefit – often using a common digital currency. Deloitte contends that it won’t be long before blockchain becomes the industry standard.

Analytics, Artificial Intelligence & Machine Learning

DEC 2018:

Another big point of conversation in MRO is data analytics, leading itself to developments in artificial intelligence as well as machine learning. While it’s a bit flashier to talk about robotics changing MRO, it would perhaps be more accurate to say that it is developments in data collection, analysis and implantation through machine learning and artificial intelligence (AI).

The above-cited issue with robotics – difficulties in dealing with variable tasks – is something that we’re already beginning to see MROs overcome. This is happening through advances in machine learning, powered by mass data that machines learn to recognise patterns in – essentially turning the variable into the predictable.

With major increases in the availability of data, pulling from the abundance of sensors present on modern aircraft and better data routers, it can be said that we’re currently sitting with the building blocks to improve processes. What is needed, though, is a way to put this data into play, to analyse it and make predictions that can effectively take the variability out of processes. This is what these advances will offer the industry.

A good example of these applications can be seen in the rise of predictive maintenance. Predictive maintenance, or the use of sensor data and maintenance logs to predict maintenance needs in advance, is already helping a number of airlines and their maintenance providers better anticipate component failure and reduce unexpected maintenance.

According to Goh Poh Loh, Executive Vice President at Singapore Technologies Aerospace Ltd, these advances may enable MROs to maintain their competitive position in an industry they’re increasingly being squeezed out of.

DEC 2023:

Of all the predictions so far, this is the one that holds up the best. AI-driven predictive maintenance, as an enabler of predictive maintenance and all-round optimisation, is without a doubt the buzzword that continues to excite the industry the most. However, while nobody disputes the potential of its real-time quality prediction, there are concerns about the lack of available data. Large amounts are simply undigitalised, non-integrated, or unobtainable, and without it there won’t be enough for Gen-AI to detect patterns not obvious to the human eye, thus enabling USM suppliers to predict when airlines might need new parts for their planes before the parts begin to fail – and keep their parts inventories suitably stocked, so there is never a shortage.

RELATED ARTICLE:

Predictive maintenance & the road to a proactive supply chain

Intelligent Machines

DEC 2018:

What happens when you start combining the above-mentioned technologies? You get intelligent machines.

Intelligent machines can be as simple as common tools made smarter by adding a Wi-Fi connection. An example of this could be the Wi-Fi connected torque wrench, which when used in conjunction with GE-tested smart glasses can instruct mechanics of the correct amount of torque to apply.

Where intelligent machines really get interesting, though, is when machine learning is combined with advanced robotics. Such an example is Lufthansa Technik’s enhanced mechanical arms.

Complete with added sensors and wireless communications, these intelligent machines have the potential to bring about human-robot collaboration by enabling robots to respond to vocal or image-based commands.

DEC 2023:

Again, a pretty astute overview from 2018 given that nobody foresaw the pandemic. Corona further accelerated the digitalisation of the sector, paving the way for all the aforementioned technologies to flourish. The pathways are open – all the industry needs to do is release its data onto them.